Monitoring & Controls

PACKAGING & CONDITIONING

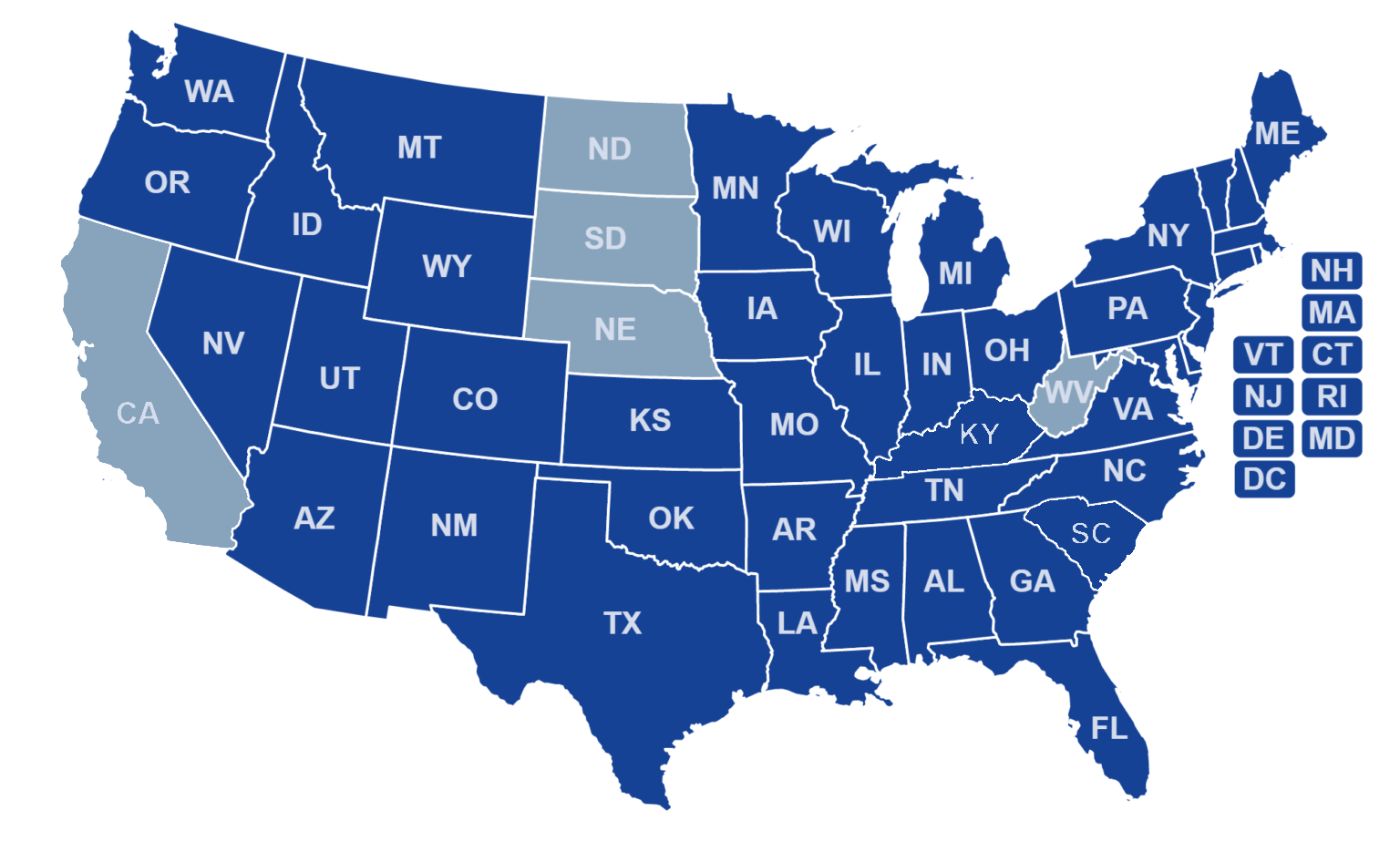

Biological samples, investigational drugs, cell and gene therapies and other life-saving medicines all have specific and unique temperature requirements. Whether as part of clinical trial or for commercial distribution, whatever the appropriate temperature range – it must be maintained as the shipment moves through the supply chain to ensure integrity and patient safety. This often requires specialized vacuum insulated packaging (VIP) shippers, which are pre-qualified to hold a particular temperature over a specified period of time – ensuring 99.9% of shipments remain within temperature. To provide just-in-time availability of these critical shippers, Red Fox Medical Courier currently has a global network of more than 10 warehouses in key locations around the world where VIP shippers are conditioned and stored.

24/7

ACCESS TO SPECIALLY

TRAINED LOGISTICS EXPERTS

- A global network of GDP compliant conditioning warehouses that incorporate best practices in cold chain management and provide the fastest turn-around time in the industry

- Consultation on the best packaging solution to ensure product integrity for all temperature ranges

- Global provisioning and placement of LN2 dry shippers conditioned for specific temperature ranges, 2-8ºC, -20ºC

- VIP inventory management system for managing the conditioning, transport, tracking, return, recycling and inventory of each unit

- Cold chain manager technology that tracks, monitors and calculates the duration of transit against package validation time – allowing our logistics team to continually monitor and intervene if shipment integrity is at risk

- Optimized route planning for the safest, most efficient route and modes of transportation

- Advanced monitoring systems that track real-time temperature combined with real-time GPS tracking with automated alerts to avoid potential delays